The beginning

A Journey Towards Excellence

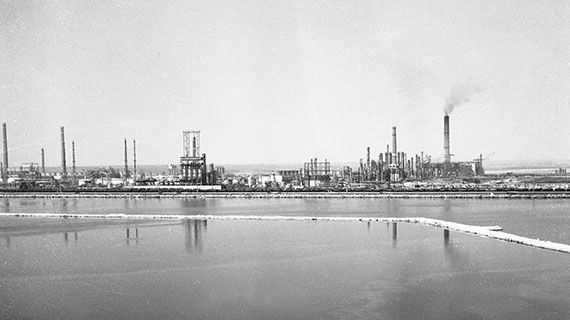

Over 45 years ago, Petromidia began to carve its history on the sea shores in Năvodari., The decision to locate the refinery here was made after an aerial survey determined that the current location met all essential conditions: proximity to the sea, a community that could be developed, and a vast available surface.

Anniversary concert of classic music

The 45th celebration marks our commitment to industrial excellence, innovation, and sustainable development, contributing significantly to both regional and national economies.

The anniversary proceedings involve a classical music concert at Constanta’s landmark cultural venue Oleg Danovski Theater, where the Royal Camerata Orchestra, conducted by Constantin Grigore will be accompanied by the Kazakh violinist Erzhan Kulibaev.

Read the full interview here.

The community of Navodari developed together with Petromidia

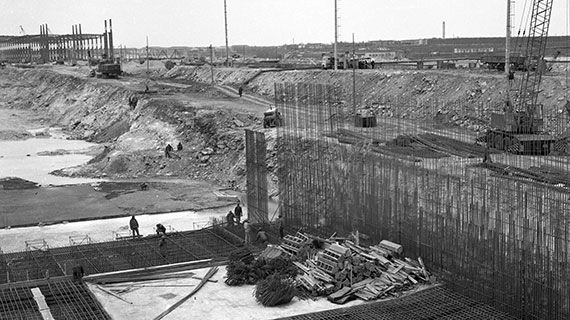

In the 1970s, the land that now hosts Petromidia was largely a swamp, but the ambition and hard work of thousands of people transformed it into one of the most modern refineries in Southeast Europe.

The development of Navodari community was closely linked to Petromidia

Navodari started as a small fishing village but grew significantly over time. In the '80s, it had 26,000 residents, and now it is one of the most important cities in Dobrogea, with 40,000 people living there.

It is not widely known that Petromidia occupies an area of 480 hectares, of which 37 hectares were recovered from the sea. The first pile marked the settlement on July 9, 1976. A considerable amount of effort was invested in ensuring the stability of the land under Petromidia, so that the entire structure can withstand an earthquake of nine degrees on the Richter scale.

The construction activities at the refinery spanned over 13 years, engaging approximately 5,000 to 6,000 workers in the process. The earliest facility, the Atmospheric Distillation Plant, was commissioned in 1979. Over time, Petromidia has grown to encompass 19 primary units and has established itself as Romania's largest refinery.

Chronology of the Petromidia Refinery

Interesting details

- In order to secure the labour force at the beginning, employees from similar complexes from all over Romania were transferred to Constanta.

- Circulation into the factory was done by foot, with personal bicycles or with the platform bicycles – about 200 bicycles.

- The first Felix computer was seen in 1985, and the first Internet connection was in the commercial manager’s office, in 1992.

- The platform is surrounded by an underground wall, 80-100 centimetres wide and 4.5 metres high, which has the role of retaining any leaks of petroleum products which might accidentally go into the soil; migration into the sea or into the lake is thus avoided.

- In order to maintain the constant level of the groundwater below the platform, there is a special system of drainage networks and special drainage stations.

- The water needed by the platform is pumped from the Danube-Black Sea Canal, by means of a pumping station located 30 km from the platform.

Post communism period

The initial goal for constructing this facility was to establish a vertically integrated industry encompassing textiles, petrochemicals, rubber, coatings, and chemical fertilizers, with crude serving as the foundational element.

From 1990 to 2000, there was a significant reorganization of markets on both domestic and international levels, leading to reduced demand for the raw materials used in synthetic yarn and fiber manufacturing. Consequently, the focus of the industrial complex shifted towards fuel and polymer production.

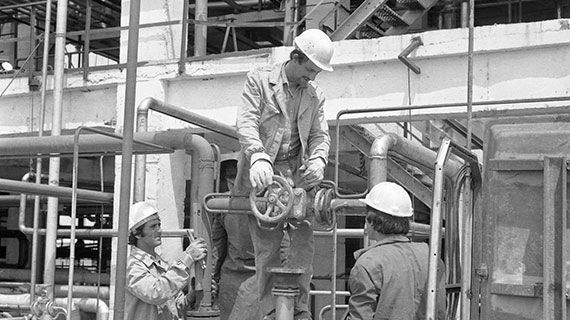

Petromidia has undergone many changes over the years, adapting to market and technological shifts.

From the early days of employees using bicycles and the first Felix computer in 1985 to the launch of an automated command and control center in 2005, the refinery has always shown a strong dedication to innovation and sustainability. The command and control center is built like a fortress, being able to resist severe natural disasters, such as earthquakes.

The largest Romanian refinery

The refinery's capacity has increased to 5 million tons thanks to continuous upgrades funded by its sole shareholder, KazMunayGas.

This has strengthened its position as a national and regional leader. The refinery has a high complexity index and can process high-sulfur crude oil into Euro 5 products only.

Petromidia operates in synergy with Vega, the Group's other refinery, which receives semi-finished products from Petromidia and turns them into value-added products. Vega is the only local producer of road bitumen and polymer-modified bitumen.

Petromidia refinery operates the only petrochemical unit in Romania.

The refinery has a marine terminal launched in 2008, located 8.6 km from the Port of Midia. The terminal delivers crude oil to the refinery through onshore and offshore pipelines.

Petromidia showed its ability to adapt continuously, especially in 2020, when it faced the COVID-19 pandemic. The refinery produced a new petrochemical sort, which was used for the filtering material in protective masks.

After struggling with market volatility and financial losses for many years, Rompetrol had one of its best years in 2022.

Petromidia is a significant industrial player in the region, breaking new production records. It supplies not only fuels but also products and raw materials for various industries and goods, both domestically and internationally.

In 2023, the refinery supplied two-thirds of its production to the local market, supporting the mobility of millions of drivers, as well as the functioning of many local industries.

Today, Petromidia remains a symbol of industrial excellence and sustainable development, a socially engaged actor through the jobs it creates and its community investments, significantly contributing to the regional and national economy and, importantly, to Europe's energy security.

Petromidia – 45 of years of development, innovation and performance

The refinery's story is the story of a committed and professional community, made up of people who, across generations, passed on the values that turned Petromidia from a project into a key industrial platform for the whole country.

Petromidia: Leader in the Refining Industry

“Petromidia is the largest local producer of fuels, the biggest refinery, and the sole producer of petrochemicals in the country. Today, we supply Romania with over two-v thirds of Euro 5 fuels. We are proud to be a leading local producer, an important contributor to the state budget, and a significant employer.”

– Florian Pop, General Manager of Rompetrol Rafinare.

140 million USD strategic investments in Petromidia and Petrochemicals

“2024 has been an important year for investments in the refinery, not only at the Petromidia platform but also in the petrochemical sector and Vega, with a total investment of 140 million USD. Beyond all investments, modernizations, digitalization, or green deals, it is the people behind it all, and without them, nothing would be possible.”

– Cristian Bolohan, Project and Investment Director, Rompetrol.

Petromidia: Diversified supply chain with a atrategic role in the region

“Thanks to its strategic positioning on the Black Sea, our refinery benefits from a continuous supply of crude oil, further secured by the unloading operations at the Midia Marine Terminal. In the Port of Midia, we have oil berths where products can be loaded for Rompetrol Group subsidiaries in Moldova, Bulgaria, Georgia, and the Mediterranean market.”

– Rodica Brăiescu, Supply Chain Manager, Rompetrol Rafinare.

Evolution and innovation at Rompetrol through the 2008-2012 investment program

“I started my journey at Rompetrol in 2006, as a result of the internship program from that year. The project that helped me evolve was the investment program from 2008- 2012, which included the implementation of the 'Delfin' project. This involved collaboration between departments and generated solutions for the development of new products: the transition from Euro 4 to Euro 5 fuels, the production of new polymer grades in petrochemicals, and the expansion of the product portfolio at the Vega refinery.”

- Anca Diaconița, Process Engineering Director, Rompetrol Rafinare.

15 Years of performance: Over 700 tankers and 61 million tons of crude oil transited through Midia Marine Terminal

“In the last 15 years, over 700 tankers and over 61 million tons of crude oil have been unloaded through this terminal, fueling Petromidia, and it is the merit of my fellow professional divers who dedicate their activity out in the Black Sea to operate this terminal every day.”

- Mihai Brinzoi, General Manager of Midia Marine Terminal.