tons

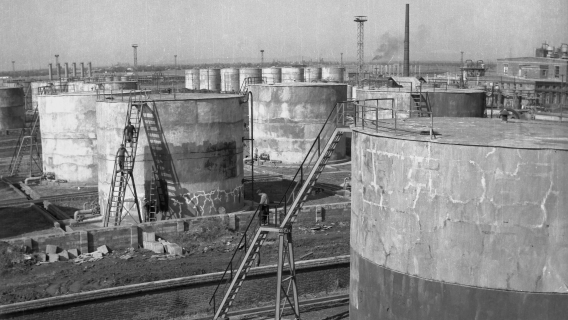

Vega Refinery

Living history of the Romanian refining industry

Vega is the second refinery of the KMG International Group, located in Ploiești, county of Prahova, its activity being integrated with Petromidia Refinery.

Built back in 1905, it is the longest standing local facility, with more than 110 years of experience. It had a complex role of specialized link between the Romanian refineries from the very beginning.

The refinery has evolved from a traditional oil refining facility to a producer and supplier of special products obtained exclusively from semi-finished products supplied by Petromidia Refinery.

Sole producer of N-Hexane, refined white spirit and bitumen in Romania

With a processing capacity in excess of 350,000 tons of feedstock/year (refined, fuel oil, A1 jet, C5-C6 fraction), Vega Refinery is well positioned as the sole producer for a number of specific products, including: normal Hexane, organic solvents, refined white spirit, and other oil products (naphtha, white spirit, heating fuel, light liquid fuel, road pavement and special bitumen).

Experience in road bitumen

Vega has a history of over 90 years in production of road bitumen. In 2007, 7 million USD were invested in the first plant for polymer-modified road bitumen in Romania. It has a capacity of 66,000 tons of bitumen, polymer-modified bitumen and special bitumen per year

The special benefits of polymer-modified road bitumen are improved elasticity and higher resistance to wear and temperature changes, with a lifetime longer by 50% and traffic noise reduction properties.

Modern automated vapor recovery system

Vega refinery has implemented a new fully automated vapor recovery unit at the auto and rail loading points. The 2.3 million USD investment effort aims at reducing the impact of the operational activities on the environment and communities in the area.

The vapor recovery unit complies with all the environmental requirements in the field of emissions of volatile organic compounds, resulting from the operations of loading and unloading of petroleum products in the automotive and rail ramps.

More details here.

Modernization of the thermal power plant

The Vega refinery will modernize the thermal power plant in the next period in order to continue reducing the impact of the activities on the environment.

The investment of over 1.9 million USD also includes the installation of a new steam boiler, produced in line with the highest standards.

The objectives of this project are mainly to improve the energy efficiency of the refinery by increasing the efficiency from 91%, at present, to about 96% and reducing the emissions resulting from the steam production process, in accordance with the provisions of the integrated environmental authorization and the legislation in force.

More details here.

Projects dedicated to energy efficiency and environmental protection

In the latest years, important projects have been successfully completed at the Vega refinery, with the main role being to reduce the impact on the environment, but also to improve operational efficiency. Among the completed actions, we list:

- Modernization of fuel storage tanks;

- Automation of the vapor recovery unit;

- Modernization of the thermal power plant;

- Installation of the new technological furnace in the Vacuum Distillation installation.

All these actions have reduced the emissions of organic compounds by over 90%, increased the energy efficiency of the refinery and last but not least have contributed to increasing efficiency.

Applications for the products of Vega Refinery of Ploiesti

Chemical and petrochemical industry; rubber industry:

polymerization solvents used to obtain polypropylene and high-density polyethylene in tire industry

Food industry:

food solvents, production of natural protein

Footwear industry:

cleaning agents for textiles and leather

Dye industry:

solvents for varnishes and adhesive components

Vega, a niche refinery in Romania

A small refinery, Vega has a special role in the local industry in Romania through the many industries that depend on the products made here: from the chemical, petrochemical and rubber manufacturing industries to the food industry.

Benefits of the current setup of Petromidia and Vega

Added-value products for the two refineries of KMG International. Vega sources feedstock 100% from Petromidia.

Better performance and enhanced flexibility for Vega Refinery driven by production and sale of 5 added-value products (hexane, ecological solvents such as gasoline SE 65/80 and SE 75/115, light naphta and naphta rich).

Higher margins for Hexane and Organic Solvents as compared to sale of refined products/C5-C6 fraction (product associated with light naphtha) for Steam Cracker, or as component for gasoline with low octane number.

The sole refinery in Romania that produces Refined White Spirit Other finished products associated: heating fuels such as non-industrial fuel type P or Rompetrol calor extra 1.

In 2018, bitumen produced in Vega provided approximately 25% of the bitumen requirement in Romania.

Finished products obtained: bitumen (road bitumen, bitumen for membranes, modified with polymers), primer (used for the protection of buried metal pipes), liquid fuels (light liquid fuel type 3, Rompetrol Calor Economic type 3, fuel oil type 40/45).

Figures that matter

Results H1 2025

The Vega Ploiesti refinery, the only producer of bitumen and hexane in Romania, processed about 181 thousand tons of raw materials in H1 2025 (a 54% increase), driven by high flows of raw and semi-finished materials delivered by Petromidia.

In the first 6 months of 2025, the refinery utilization rate increased by 59.57% compared to the same period last year. The Vega refinery recorded good operational parameters, with an energy consumption of 2.65 GJ/t and a technological loss of 0.69%.

Read more about the financial and operational results in H1 2025

| Indicators H1 2025 | ||

|---|---|---|

|

181.000 k

tons feedstock processed

|

0.69%

technological consumptio

|

2.65Gj/mt

Energy consumption

|

Results 2024

The Vega Ploiesti refinery, the only producer of bitumen and hexane in Romania, processed about 293 thousand tons of raw materials, which is below the level of the previous year, a level directly determined by the quantities of raw materials and semi-finished products received from the Petromidia refinery.

The Vega refinery recorded good operational results in areas such as energy consumption – 2.69 GJ/ton and technological consumption – 0.8%.

Read more about the financial and operational results in 2024

| 2024 | ||

|---|---|---|

|

292.789k

tons feedstock processed

|

0.8%

technological consumptio

|

2.69Gj/mt

Energy consumption

|

Vega, a living history of the Romanian refining industry