Action plan

Significant Environmental Investments

Between 2002 and 2011, Rompetrol successfully removed approximately 80,000 tons of waste — far surpassing the privatization commitment — through an investment of $17.4 million.

Our commitment to environmental protection has been demonstrated through continuous remediation initiatives, including:

- Completion of remediation works for Historical Lagoons 18 and 17 in 2022, two of the largest lagoons on the Vega Refinery site.

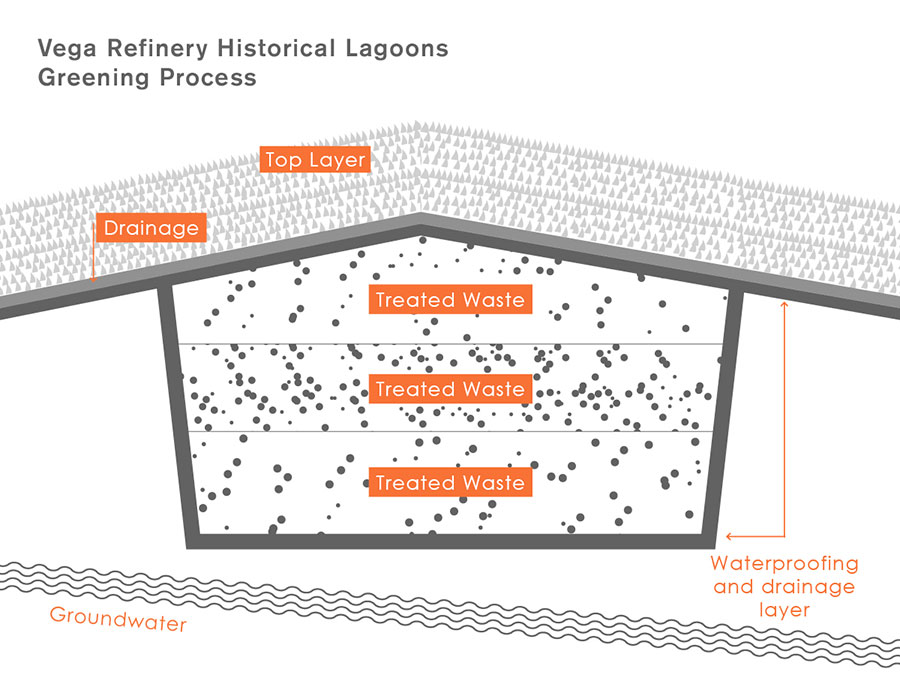

Key actions included: - Draining accumulated water from the lagoons

- Excavating, treating, and stabilizing acid tars and petroleum waste

- Reinforcing and converting the lagoons into safe storage sites for stabilized solid waste, using geomembrane liners with online monitoring systems

- Backfilling Lagoon 18 with treated and stabilized materials

- In 2024, Rompetrol finalized the tender process for remediation works on Lagoons 19 and 20, signing a service contract with the consortium of ARTERA BLUE SRL and SALUBRIS WASTE MANAGEMENT SRL.

- Simultaneously, Rompetrol completed the necessary documentation to obtain environmental authorities’ approval for implementing a simplified closure solution, in compliance with Government Ordinance 2/2022.

By launching new project phases, we reaffirm our firm commitment to completing this major environmental protection effort.

Action Plan for 2025 — Continuing the Remediation of Historical Lagoons

In 2025, , Rompetrol Rafinare continues its environmental protection objectives, allocating approximately, $20 million for the remediation and ecological restoration program at the Vega Ploiești Refinery.

Key planned activities for 2025 include:

- Excavation and treatment works for waste from Lagoons 19 and 20, advancing the overall remediation process.

- Regulatory approval and implementation of the alternative simplified closure solution.

- Contribution of approximately 14.2 million RON to the closure fund, managed by the Environmental Fund Administration, based on the updated technical project for the simplified closure of the waste disposal site.

Air Quality Monitoring

To protect the local community and ensure transparency, Vega Refinery has implemented an automated air quality monitoring network within a 2-kilometer radius. This system allows:

- Real-time monitoring of the environmental impact of operations

- Integration of data into the refinery’s environmental management systems

- Immediate corrective actions to maintain air quality indicators within legal limits, even when external factors such as traffic or nearby industrial activities influence air quality.

Through these actions, Rompetrol Rafinare demonstrates its ongoing commitment to minimizing industrial impact on the community.

Innovative Solutions and Technologies

Rompetrol Rafinare has invested significant time and resources in selecting the most advanced companies and safest technologies to neutralize and treat the acid tars accumulated over the years. These acid tars originated from fuel production and crude oil refining processes. Their elimination is carried out through a sustainable strategy focused on safety and environmental protection.

Adopted Technological Solution

- On-site stabilization and safe storage — Acid tars are treated and converted into a solid, stable waste form, eliminating risks to human health and the environment.

A critical factor in selecting this solution was its long-term sustainability. Rompetrol Rafinare is committed to monitoring the site and surrounding groundwater for 30 years after project completion.

Materials Used — Safety and Compliance

- Internationally certified solutions for the stabilization and treatment of acid tars similar to those in the Vega lagoons

- High-performance binding agents compliant with all national and international standards

- Materials that pose no risk to human health or the environment, fully aligned with regulatory requirements

Environmental and Community Protection

To protect nearby residents and minimize the impact of remediation works, the refinery — in collaboration with local and national authorities — has implemented a comprehensive program of measures:

All operations are under constant supervision, and noise measurements are taken at the refinery's fence line to ensure compliance with applicable regulations.

Strict Safety and Cleanliness Measures

Waste transport is conducted through a dedicated refinery route using trucks equipped with sealed covers, passing through a wheel-washing station to prevent road contamination.

Stabilized waste materials are transported in sealed cement trucks, fully certified to meet legal safety standards.

Transport of neutralized waste destined for recovery is carried out only after notifying the Inspectorate for Emergency Situations, following pre-approved routes.

For the supply of necessary materials and the evacuation of treated acid tars to authorized recovery points, a dedicated access route to DN1B – Ploiești ring road has been established, following the route: Blejoi roundabout → Rompetrol gas station → Railway area near Blejoi City Hall → Vega Refinery Gate 2.